For thick materials

Oxy-fuel cutting

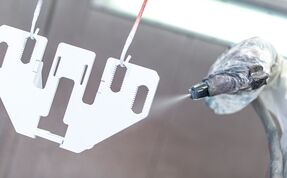

Oxy-fuel cutting is a cutting method for thick steel plates that is more than 100 years old. Even today, it is among the most important cutting methods for metal fabrication. During the cutting process, the point of separation is heated to its kindling temperature and subsequently separated by a stream of gas. This burns the metal, which is why this process is also called flame cutting.

Oxy-fuel cutting

at Härtwig Maschinenbau

Our CNC oxy-fuel cutting machine is capable of precisely cutting steel plates up to 360 millimeters thick and with maximum plate dimensions of 6,000 x 2,000 millimeters.