Refining workpieces

Deburring & marking

Deburring removes the Poisson burrs, rollover burrs, and tear burrs that remain attached to a workpiece, primarily after metal fabrication. Burrs may negatively affect the function of the element within the final product and even cause significant injuries.

The term “deburring” is mostly used in the metalworking industry. Marking the workpieces is also important: Many components need to be marked, regardless of whether the intended marking is the corporate logo, the part number, or a set of symbols for the subsequent assembly. The prevalent methods facilitate tamper-proof marking.

Deburring

at Härtwig Maschinenbau

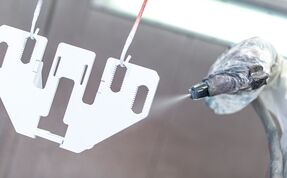

Burrs are removed by means of brushing, filing, counterboring, grinding, milling, barrel finishing, thermal deburring, electrochemical deburring, high pressure water jet deburring, abrasive flow machining (AFM), hydro-erosive grinding (HEG), ultrasonic deburring, or cutting processes. Small components are frequently deburred by means of barrel finishing.

Marking

at Härtwig Maschinenbau

Different technologies are used for marking the components. Härtwig Maschinenbau GmbH & Co. KG offers marking by means of a dot peen marking machine, a mobile color printer, or labels.