Joining components

by fusion

Welding

Almost everybody knows the fabrication process »welding«. According to DIN standard 1910-100, welding “permanently joins components by means of heat and/or pressure, with or without filler metals.” »Permanent fusion joints« are formed by means of heat or pressure, optionally with a filler metal, between components when welding. Literature distinguishes »joint welding« and »buildup welding« used for depositing weld metal on workpieces. Welding is primarily used in metal fabrication.

Welding

at Härtwig Maschinenbau

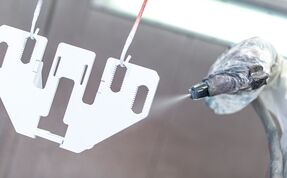

We fabricate welded assemblies up to 2 tons by means of various welding processes, e.g., MIG, MAG, WIG, and spot welding. Welded assemblies exhibiting dimensions up to 1,200 x 1,000 millimeters can be fabricated in our robotic MAG welding cell. Our employees are exceptionally trained and take part in professional development workshops and pass recertification exams at regular intervals.