For complex

geometries

Turning & milling

CNC turning facilitates automatically machining workpieces with intricate shapes or geometric properties. The so-called »repeatability« ensures a high level of efficiency. CNC turned parts are suitable for a variety of applications, e.g., in the automotive industry as well as mechanical and plant engineering projects, and in small dimensions in medical devices and electrical engineering designs. In that context, small, medium, and large batches can be realized in a cost-efficient manner.

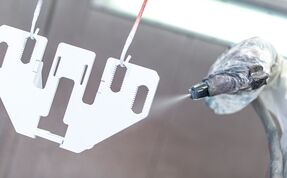

CNC milling is a process utilizing rotary cutters for machining workpieces with a high level of precision by means of modern control technology. CNC machining centers can achieve high cutting speeds; consequently, they primarily operate in a cost-efficient manner in mass production applications. CNC milling is not limited to metal machining, but instead is also used for plastics machining and woodworking.

CNC turning

at Härtwig Maschinenbau

Our live tool CNC lathes are capable of machining workpieces exhibiting a length up to 1,000 millimeters and a maximum diameter of 500 millimeters. Material exhibiting a diameter of up to 700 millimeters can be used when automatically feeding by means of a bar feeder.

CNC milling

at Härtwig Maschinenbau

Our modern CNC machining centers achieve top precision for the maximum machining dimensions of 2,100 x 860 x 910 millimeters.